Mobile phone:13669875810

Mail:yong8mei@cnhybond.com

ADD:si ma industry zone,chang ping town,dong guan city,china

975( halogen-free)Water based Adhesion promoter/primer

1. Product introduction

CNHYBOND-975 adhesion promoter is a water-based polymer polymerized ,

Add a small amount 975 in water-based paints( coatings, and glues. The ink);it is used to promote adhesion of waterbase coat,ink,printing,uv varnish,resin etc ,iexcellent adhesion, flexibility and tear resistance,

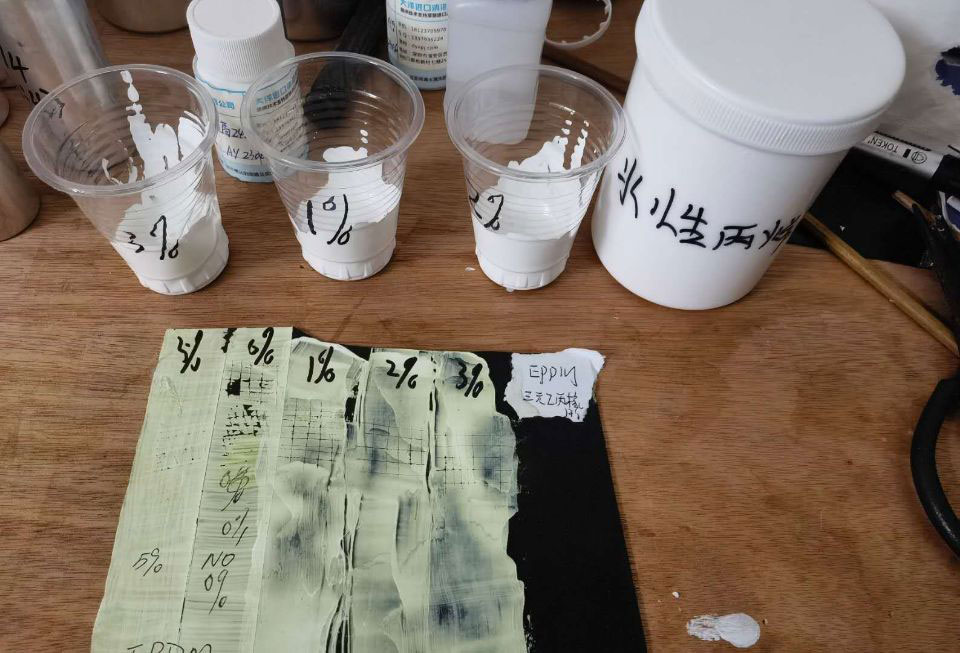

It can also be primer with EPDM, PP, PET, TPE, BOPP, TPU, TPO, Abs, PVC, NR, NBR, SBS rubber materials, glass, metal and other substrates ; it may promote adhesion of this surface to bonding, painting, silk printing, and thermal transfer

2:performance

CNHYBOND975 water-based adhesion promoter/primer is halogen-free, environmentally friendly, non-toxic and harmless, with good chemical stability, and is an environmentally friendly product.

1. Product introduction

CNHYBOND-975 adhesion promoter is a water-based polymer polymerized ,

Add a small amount 975 in water-based paints( coatings, and glues. The ink);it is used to promote adhesion of waterbase coat,ink,printing,uv varnish,resin etc ,iexcellent adhesion, flexibility and tear resistance,

It can also be primer with EPDM, PP, PET, TPE, BOPP, TPU, TPO, Abs, PVC, NR, NBR, SBS rubber materials, glass, metal and other substrates ; it may promote adhesion of this surface to bonding, painting, silk printing, and thermal transfer

2:performance

1. Appearance: milky white low-viscosity organic aqueous solution

2. Dilution: polymer resin emulsion, diluted with pure water.

3. Storage stability: It needs to be stored in an indoor environment of 10-40℃,

shelf life :1 year(at room temperature)

4: Density: 1.0g/cm3

5: Solution: pure water

3: Chemical composition

A polymer resin composed of acrylic and epoxy.

4:Add dosage

1:Add resin (paint, ink, resin, glue)

1%-5% (test before use)

2:primer: 972: purified water=1: (1-10)

(please test before use)

5:use

Used as primer:

1. If there are many release agents or oily substances on the

surface of materials such as EPDM, it is recommended to clean them with organic solvents first.

2. Shake the treatment agent and let it stand for 10 minutes

to defoam, and evenly coat it on the surface of other materials ,such as EPDM (supports fine-bristle brushing, spraying, rolling, dipping, screen printing, etc.), and dry at room temperature for 15 -30 minutes to completely volatilized and transparent,

such as thermal activation in an infrared oven at 60-80 degrees Celsius for 3-5 minutes, the treatment effect will be better.

3. After the treatment agent is dried (baked), you can apply

water-based glue, printing, spray paint or water-based double-sided adhesive. The specific operation depends on the type of adhesive. It is recommended to cooperate with our company's products to ensure quality. It is recommended to try the 972 adhesion promoter/primer before using it to avoid mistakes. If the material changes or other special

Please contact our company in time because of the deviation of adhesion.

6: packaging and storage

Packing: 20KG/barrel,

Put it in a cool and ventilated place, keep the container tight,

Shelf time:

12 months (calculated from the production date under normal storage conditions without opening the lid

7:NOTE:

The data contained herein are furnished for information only and are believed to be reliable. We cannot assume responsibility for ther results obtained by others over whose methods we have no control.it is they user,s responsibility to determine suitability for the user,s purpose of any production methods mentioned herein and to adopt such precautions as many be advisable for the protection of property and of persons against any hazards that may be involved in the handling and use thereof.

.